This press brake is hydraulically driven, with cylinders controlling the vertical movement of the punch and die. The welded frame structure provides high rigidity and easy installation.

The machine utilizes an advanced electro-hydraulic proportional synchronization system, integrating a grating ruler on the C-frame, CNC control system, and proportional valve to form a closed-loop servo control. This ensures precise speed and position control of the ram, maintaining high parallelism and repeatable positioning accuracy.

Equipped with a specialized CNC system (e.g., CT-8, CT-12, CT-15, DA-53T, DA-58T), the system supports up to 12 axes, including Y1, Y2, X, R, and V axes, as well as optional tool changer, robotic arms, and compensation axes, offering maximum flexibility to meet diverse production needs.

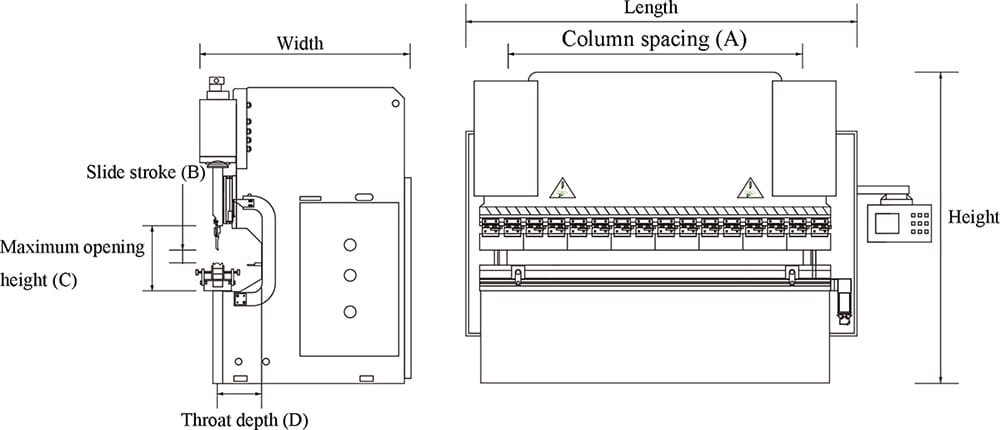

| Model | Nominal Pressure (kN) | Workbench Length (mm) | Column Spacing (mm)(A) | Slide Stroke (mm)(B) | Max. Opening Height (C) | Throat Depth (mm) (D) | Workbench Height (mm) | Rapid Decent Speed (mm/s) | Decent Speed (Slow Speed Mode) (mm/s) | Return Speed (mm/s) | Main Motor Power (kW) | Oil Tank Capacity (L) | Backgauge X-Axis Stroke | Weight |

| XSM 50/1500 | 500 | 1500 | 1200 | 165 | 420 | 250 | 850 | 250 | 10 | 200 | 5.5 | 180 | 600 | 3.7T |

| XSM 80/2500 | 800 | 2500 | 2100 | 165 | 420 | 250 | 930 | 230 | 10 | 180 | 7.5 | 280 | 600 | 5.8T |

| XSM 110/3200 | 1100 | 3200 | 2700 | 205 | 460 | 400 | 930 | 220 | 10 | 160 | 7.5 | 300 | 600 | 7.8T |

| XSM 130/3200 | 1300 | 3200 | 2700 | 205 | 460 | 400 | 930 | 200 | 10 | 160 | 11 | 300 | 600 | 8.6T |

| XSM 170/3200 | 1700 | 3200 | 2700 | 205 | 460 | 400 | 930 | 180 | 10 | 130 | 11 | 400 | 600 | 10.8T |

| XSM 220/3200 | 2200 | 3200 | 2700 | 205 | 460 | 400 | 930 | 180 | 10 | 130 | 18.5 | 400 | 600 | 11.5T |

| XSM 250/3200 | 2500 | 3200 | 2700 | 250 | 520 | 405 | 900 | 140 | 8 | 100 | 18.5 | 450 | 600 | 16.5T |

| XSM 320/3200 | 3200 | 3200 | 2600 | 250 | 520 | 405 | 900 | 130 | 8 | 100 | 22 | 500 | 600 | 17.6T |

| XSM 400/3200 | 4000 | 3200 | 2600 | 300 | 540 | 405 | 900 | 120 | 7 | 90 | 30 | 650 | 600 | 20.5T |

| XSM 110/4000 | 1100 | 4000 | 3300 | 205 | 460 | 400 | 930 | 220 | 10 | 160 | 7.5 | 350 | 600 | 8.8T |

| XSM 130/4000 | 1300 | 4000 | 3300 | 205 | 460 | 400 | 930 | 200 | 10 | 160 | 11 | 350 | 600 | 9.5T |

| XSM 170/4000 | 1700 | 4000 | 3300 | 205 | 460 | 400 | 930 | 180 | 10 | 130 | 11 | 450 | 600 | 11.5T |

| XSM 220/4000 | 2200 | 4000 | 3300 | 205 | 460 | 400 | 930 | 180 | 10 | 130 | 18.5 | 450 | 600 | 12.8T |

| XSM 250/4000 | 2500 | 4000 | 3300 | 250 | 520 | 405 | 900 | 140 | 8 | 100 | 18.5 | 450 | 600 | 18T |

| XSM 320/4000 | 3200 | 4000 | 3200 | 250 | 520 | 405 | 900 | 130 | 8 | 100 | 22 | 500 | 600 | 19.6T |

| XSM 400/4000 | 4000 | 4000 | 3200 | 300 | 540 | 405 | 900 | 120 | 7 | 90 | 30 | 650 | 600 | 22T |

| XSM 170/6000 | 1700 | 6000 | 5000 | 205 | 460 | 405 | 1250 | 180 | 10 | 110 | 15 | 500 | 600 | 18.8T |

| XSM 250/6000 | 2500 | 6000 | 5000 | 250 | 520 | 405 | 1250 | 180 | 8 | 100 | 22 | 580 | 600 | 22T |

| XSM 320/6000 | 3200 | 6000 | 5000 | 250 | 520 | 405 | 1250 | 130 | 8 | 90 | 26 | 650 | 600 | 28T |

| XSM 400/6000 | 4000 | 6000 | 5000 | 300 | 560 | 405 | 1250 | 120 | 7 | 80 | 30 | 750 | 600 | 36T |

The CybTouch 8 features a clear, high-resolution touchscreen with a highly integrated set of functions. Thanks to its interactive touch interface, it offers large icon buttons, an intuitive layout, online assistance, and various automated functions, providing continuous guidance for operators.

Designed for ease of use, the CybTouch 8 is particularly well-suited for installation on a swing arm, ensuring convenient operation and accessibility.

The backgauge is constructed with a ball screw, linear guide, and adjustable lifting stop, ensuring smooth and precise positioning. The standard configuration includes CNC-controlled X and R axes, with backgauge fingers that can be adjusted laterally to accommodate different material widths. A manual fine-tuning mechanism is also included for enhanced accuracy.

The backgauge beam undergoes annealing treatment and is processed using a gantry machining center, providing high stability and superior precision.

The punch is made from forged alloy steel, precisely machined using CNC processing. The surface can be treated with black oxide coating for rust prevention and is available in customized segmented designs.

The die features a concentric design, ensuring high efficiency in die opening transitions, optimizing performance and adaptability.

The frame is constructed as a single welded structure, integrating the left and right columns, oil tank, worktable, and bottom beam. This design ensures high strength, superior stability, and precision.

The entire frame is machined on a floor-type boring machine, guaranteeing high accuracy and a stable structure, making installation and calibration more efficient.

Utilizing advanced finite element analysis (FEA) for structural optimization, the frame is designed to minimize deformation while maintaining maximum strength.